Cell Testing Procedures and Safe Operation

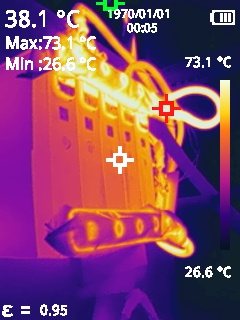

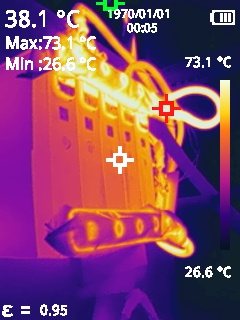

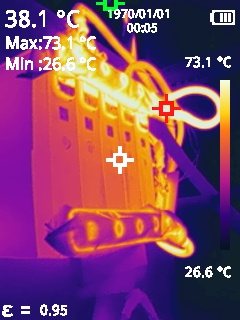

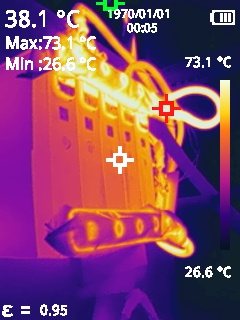

Cell Testing Thermal View

Cell Testing Thermal View

Cell Testing Procedures and Safe Operations Introduction Cell testing is a crucial process in ensuring the quality, performance and safety of the batteries. Proper procedures and safe operations are essential to minimize risks and ensure accurate results. . Pre-Test Preparations:

1. Workspace Setup: Choose a well-ventilated area with proper lighting and access to necessary equipment.

2. Safety Gear: Wear appropriate personal protective equipment (PPE) such as gloves, safety goggles and lab coats.

3. Equipment checks: Inspect testing equipment for any damages or malfunctions. Calibrate as necessary.

4. Review Procedures: Familiarize yourself with the testing procedures outlined in this document. . Cell Testing Procedures: There are various tests performed on cells, some common examples include:

1. Visual Inspection: Examine the cells for any physical damages, leaks or abnormalities.

2. Voltage Testing: Use a multi-meter to measure the voltage of each cell. Record the readings accurately.

3. Capacity Testing: Perform capacity tests to determine the energy storage capacity of the cells. Follow manufacturer guidelines or standardized testing protocols.

4. Temperature Testing: Monitor the temperature of the cells during testing to ensure they remain within safe operating limits.

5. Data Recording: Record all test data carefully, including voltage, current, temperature and any observations made during the test.

6. Analysis: Analyse the data to assess the cell’s performance and health.

7. Internal Resistance Test: Measure the cell’s internal resistance with a specialized equipment, which can impact its performance.

. Post-Test Procedures:

• Power down all equipment.

• Disconnect the cell from the testing setup.

• Dispose of the cell according to regulations or prepare it for further testing if applicable. Additional Considerations:

• Always follow the manufacturer's recommendations for charging and discharging protocols.

• Never exceed the specified voltage or current limits for the cell.

• Be aware of the potential hazards associated with different cell chemistries, such as flammability or explosion risks. Safe operation Practices:

1. Handling Precautions: Handle cells with care to prevent physical damages or short circuits.

2. Avoid Mixing: Do not mix cells of different chemistries, voltages, or capacities during testing.

3. Proper Ventilation: Ensure adequate ventilation in the testing area to prevent the accumulation of harmful gases.

4. Temperature control: Maintain ambient temperatures within recommended ranges to prevent overheating or freezing of cells.

5. Emergency Procedures: Familiarize yourself with emergency protocols, including evacuation routes and procedures for handling battery-related accidents.

6. Regular Maintenance: Perform routine maintenance on testing equipment to ensure accurate and reliable results.

7. Training and Supervision: Only trained and authorized personnel should conduct cell testing. Supervision may be required for inexperienced operators.

Conclusion: Cell testing is a critical process that requires adherence to established procedures and safety precautions. By following the guidelines outlined in this document, you can ensure accurate testing results and minimize risks associated with battery operations.

Battery pack prepartion safety measures

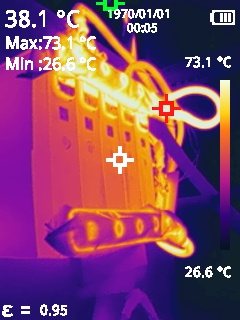

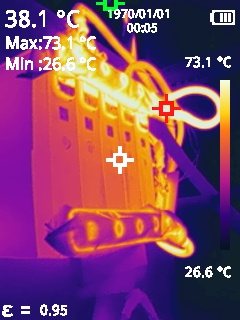

Battery Pack Thermal View

Battery Pack Thermal View

Title: Safety Measures for Battery Pack Preparation

Introduction: Battery packs are essential components in various devices, ranging from consumer electronics to electric vehicles. However, the preparation of battery packs requires careful consideration of safety measures to prevent accidents such as short circuits, overheating, and fires. This document outlines essential safety measures to be followed during the preparation of a battery pack.

1.

Choose High-Quality Components:

•

Select high-quality batteries from reputable manufacturers with proven safety records.

•

Use appropriate battery management systems (BMS) to monitor and control battery performance.

2.

Design Considerations:

•

Ensure proper ventilation and cooling to prevent overheating.

•

Design the pack layout to minimize the risk of short circuits and thermal runaway.

•

Provide adequate insulation and spacing between battery cells to prevent electrical arcing.

3.

Handling and Storage:

•

Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses when handling batteries.

•

Store batteries in a cool, dry place away from direct sunlight and moisture.

•

Avoid stacking batteries or placing heavy objects on top of them to prevent physical damage.

4.

Charging:

•

Use a dedicated battery charger designed for the specific battery chemistry and voltage.

•

Follow the manufacturer's recommended charging parameters and never overcharge the batteries.

•

Charge batteries in a well-ventilated area and avoid charging them near flammable materials.

5.

Discharging:

•

Use batteries within their specified voltage and current limits to prevent over-discharging.

•

Avoid short-circuiting battery terminals, as this can lead to thermal runaway and fire.

•

Dispose of batteries properly according to local regulations when they reach the end of their lifespan.

6.

Inspection and Maintenance:

•

Regularly inspect battery packs for signs of physical damage, leakage, or swelling.

•

Test the voltage and capacity of individual cells periodically to ensure balanced performance.

•

Replace damaged or degraded batteries promptly to prevent safety hazards.

7.

Transportation:

•

Follow transportation regulations for shipping batteries, especially lithium-ion batteries, which may have specific requirements.

•

Use appropriate packaging and labelling to indicate the presence of batteries and their hazardous nature.

•

Avoid exposing batteries to extreme temperatures during transportation.

8.

Emergency Preparedness:

•

Have fire extinguishing equipment readily available in areas where batteries are handled or stored.

•

Establish emergency procedures and train personnel on how to respond to battery-related incidents.

•

Evacuate the area and contact emergency services immediately in case of a battery fire or explosion.

Conclusion: Preparation of battery packs requires strict adherence to safety measures to prevent accidents and ensure the reliable operation of devices. By following the guidelines outlined in this document, you can minimize the risk of hazards associated with battery handling, charging, and storage, thereby ensuring the safety of personnel and property. Always prioritize safety when working with batteries.

Cell Testing Procedures and Safe Operation

Charging Station Thermal View

Charging Station Thermal View

Title: The Present Charging Station Scenario in India and New Guidelines

Introduction: As India accelerates its transition towards electric mobility, the development of charging infrastructure plays a pivotal role in supporting the widespread adoption of electric vehicles (EVs). This document provides an overview of the present charging station scenario in India and highlights the new guidelines introduced to facilitate the growth of charging infrastructure.

Present Charging Station Scenario:

1. Government Initiatives:

The Government of India has launched several initiatives to promote electric mobility and encourage the establishment of charging infrastructure.

Under the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME) scheme, subsidies and incentives are provided for setting up public charging stations (PCS) across the country.

Various state governments have also announced policies and incentives to support the deployment of charging infrastructure.

2. Charging Infrastructure Development:

Significant progress has been made in the establishment of charging infrastructure, with both public and private entities investing in charging stations.

Major cities and urban centres have witnessed a growing number of charging stations, particularly in commercial areas, shopping malls, and public parking facilities.

Charging infrastructure providers are deploying a mix of AC and DC fast chargers to cater to different charging needs and vehicle types.

3. Challenges:

Despite progress, the charging infrastructure in India still faces challenges such as high upfront costs, lack of standardized charging protocols, and limited availability of charging stations in rural areas.

Range anxiety remains a concern for EV owners, highlighting the need for a denser network of charging stations across highways and intercity routes.

New Guidelines for Charging Stations:

1. Bharat EV Charger Specifications:

The Bureau of Indian Standards (BIS) has introduced specifications for Bharat EV chargers to ensure interoperability and compatibility with EVs manufactured in India.

These standards cover both AC and DC chargers, defining parameters such as voltage, current, and communication protocols.

2. Open Access for Charging Infrastructure:

The Government has proposed guidelines to enable open access for EV charging infrastructure, allowing multiple service providers to operate and utilize the same charging stations.

Open access promotes competition, reduces monopolistic practices, and enhances the accessibility of charging facilities for EV users.

3. Ease of Doing Business:

Simplified regulatory procedures and faster approvals are being implemented to streamline the process of setting up charging stations.

Single-window clearance mechanisms and online application portals are being developed to facilitate the establishment of charging infrastructure.

4. Standardization and Interoperability:

Efforts are underway to standardize charging connectors, protocols, and payment systems to ensure interoperability and seamless user experience across different charging networks.

Common standards enhance convenience for EV users and encourage the adoption of electric vehicles.

Conclusion: The charging station scenario in India is evolving rapidly, driven by government policies, industry initiatives, and technological advancements. The introduction of new guidelines aimed at standardization, open access, and ease of doing business is expected to further accelerate the deployment of charging infrastructure and support the growth of electric mobility in the country. Continued collaboration between government agencies, industry stakeholders, and EV manufacturers will be crucial in achieving the vision of a sustainable and robust charging ecosystem across India.

Cell Testing Thermal View

Cell Testing Thermal View

Battery Pack Thermal View

Battery Pack Thermal View

Charging Station Thermal View

Charging Station Thermal View